Omexom Accelerates its Processes with EPLAN Cogineer

How Automated Engineering also Expedites Costing

The Omexom Automation business unit of Omexom Smart Technologies uses EPLAN Cogineer in an unconventional way. Cogineer’s macro-based schematic generation, which is also largely automated, is used not only for designing schematics but also beforehand, for preparing bids – an approach that offers several clear advantages.

When it comes to automating continuous processes, the Omexom Automation business unit in Uedem, Germany, is the first port of call for many plant system manufacturers and operators. Here is where Omexom Smart Technologies has consolidated its expertise in automation technology – including switchgear system manufacturing – for three industries: extraction (including for instance gravel and sand plants), foodstuff production and water/wastewater technology.

One-Stop Shop for Complex Automation Technology

Omexom offers these industries complex automation technology and turnkey solutions – from designing to panel building to commissioning and, if needed, even complete electrical infrastructure for building envelopes. This isn’t typical in the fragmented market of electrical automation but is a tradition for Omexom. The company site in Uedem was initially part of the family-owned Horlemann Group, which was acquired by VINCI Energies in 2017, and, with its many business units, is also a one-stop shop for planning and designing. The Omexom brand for energy infrastructure is part of VINCI Energies, which in turn belongs to the international VINCI Group, which has an annual turnover of around 50 billion euros.

Omexom Automation’s tradition and the company’s extensive internal resources thus form a solid foundation for a high degree of expertise in automation, particularly for process engineering plant systems.

Always Open to Innovation

Another attribute found throughout the company’s history is its openness to new development and planning tools. Omexom Automation Managing Director Thomas Willems explains: “When, for instance, a software provider presents an innovation, we test it.” As one example of this, Volker Hellmann’s electrical engineering team has been using EPLAN Pro Panel for three-dimensional control cabinet designs for almost ten years. The results are implemented 1:1 in the company workshops with a high degree of automation – for instance using a sheet metal processing system and mobile systems for wire pre-processing. Both of these systems get their data through EPLAN Platform, which Omexom uses extensively.

The Omexom Automation business unit of Omexom Smart Technologies uses EPLAN Cogineer in an unconventional way. Cogineer’s macro-based schematic generation, which is also largely automated, is used not only for designing schematics but also beforehand, for preparing bids – an approach that offers several clear advantages.

When it comes to automating continuous processes, the Omexom Automation business unit in Uedem, Germany, is the first port of call for many plant system manufacturers and operators. Here is where Omexom Smart Technologies has consolidated its expertise in automation technology – including switchgear system manufacturing – for three industries: extraction (including for instance gravel and sand plants), foodstuff production and water/wastewater technology.

One-Stop Shop for Complex Automation Technology

Omexom offers these industries complex automation technology and turnkey solutions – from designing to panel building to commissioning and, if needed, even complete electrical infrastructure for building envelopes. This isn’t typical in the fragmented market of electrical automation but is a tradition for Omexom. The company site in Uedem was initially part of the family-owned Horlemann Group, which was acquired by VINCI Energies in 2017, and, with its many business units, is also a one-stop shop for planning and designing. The Omexom brand for energy infrastructure is part of VINCI Energies, which in turn belongs to the international VINCI Group, which has an annual turnover of around 50 billion euros.

Omexom Automation’s tradition and the company’s extensive internal resources thus form a solid foundation for a high degree of expertise in automation, particularly for process engineering plant systems.

Always Open to Innovation

Another attribute found throughout the company’s history is its openness to new development and planning tools. Omexom Automation Managing Director Thomas Willems explains: “When, for instance, a software provider presents an innovation, we test it.” As one example of this, Volker Hellmann’s electrical engineering team has been using EPLAN Pro Panel for three-dimensional control cabinet designs for almost ten years. The results are implemented 1:1 in the company workshops with a high degree of automation – for instance using a sheet metal processing system and mobile systems for wire pre-processing. Both of these systems get their data through EPLAN Platform, which Omexom uses extensively.

Volker Hellmann (left) and Thomas Willems (right) implemented an unconventional idea at Omexom: using macro-based electrical engineering with EPLAN Cogineer right at the beginning, to help prepare bids.

© Omexom

Volker Hellmann (left) and Thomas Willems (right) implemented an unconventional idea at Omexom: using macro-based electrical engineering with EPLAN Cogineer right at the beginning, to help prepare bids.

© Omexom

From P8 to Cogineer

The openness to innovations also led to the electrical engineers in Uedem becoming early adopters of EPLAN Cogineer – an ECAD planning tool that allows for the automated generation of schematics based on macros. The concept and its implementation at the workplace immediately won them over. Hellmann: “Automated schematic generation with Cogineer offers real benefits. We save a lot of time. There also isn’t any risk of errors being passed along because of how the macros are maintained. That’s also why all the design data is always up to date. And if a component manufacturer changes a component or introduces a new one, we only have to input the new data once, with minimal effort.”

The question as to whether this automated schematic generation also makes sense for custom manufacturing or very heterogeneous projects is one that is answered with an unequivocal yes by Omexom management. Willems: “The functional modules such as drives, sensors and power supplies are always identical, and we’ve created macros for them. We differentiate them according to the three sectors that make up our main target groups. For instance, for water/wastewater technology we’ve stored components from several different suppliers because our customers often specify the manufacturers here. Which is why the macros offer more choices in this area.”

Preparing a Bid in Half the Time

In an approach that is typical for Omexom, the electrical engineers didn’t just settle for the usual advantages of macro-based schematic generation. They also forged a new path – implementing EPLAN Cogineer even earlier, already during the bidding phase.

Willems: “The initial idea was that we would take a completely different approach. When we receive a query, we no longer employ our regular cost calculations. Instead, the engineering department just transfers the specifications data from the query into Cogineer. You don’t even need any specialty knowledge of ECAD.” All the customer requirements are simply entered into a configurator interface.

This very simple step enables the automatic creation of a bill of materials, which is transferred to the Omexom costing program via an XML interface. The program then outputs the bid price, which has proven to very closely approximate the actual costs in practice. EPLAN Cogineer is thus already working very reliably in this phase and has cut the time required to prepare a bid by about half.

Additional Time Savings in Electrical Engineering

When the customer accepts the bid and places the order, additional time savings accrue. Willems: “We can then design normal-sized projects in about two to three days – it used to take up to three times longer. And procurement can begin ordering components immediately since the bill of materials is already available.” This speed not only leads to shorter throughput times, it is sometimes also decisive when it comes to orders being placed. Hellmann: “In these cases, it’s not just to our advantage to be able to quickly design and manufacture. Customers also appreciate it when we can show them plans and views of their projects very early on.”

From P8 to Cogineer

The openness to innovations also led to the electrical engineers in Uedem becoming early adopters of EPLAN Cogineer – an ECAD planning tool that allows for the automated generation of schematics based on macros. The concept and its implementation at the workplace immediately won them over. Hellmann: “Automated schematic generation with Cogineer offers real benefits. We save a lot of time. There also isn’t any risk of errors being passed along because of how the macros are maintained. That’s also why all the design data is always up to date. And if a component manufacturer changes a component or introduces a new one, we only have to input the new data once, with minimal effort.”

The question as to whether this automated schematic generation also makes sense for custom manufacturing or very heterogeneous projects is one that is answered with an unequivocal yes by Omexom management. Willems: “The functional modules such as drives, sensors and power supplies are always identical, and we’ve created macros for them. We differentiate them according to the three sectors that make up our main target groups. For instance, for water/wastewater technology we’ve stored components from several different suppliers because our customers often specify the manufacturers here. Which is why the macros offer more choices in this area.”

Preparing a Bid in Half the Time

In an approach that is typical for Omexom, the electrical engineers didn’t just settle for the usual advantages of macro-based schematic generation. They also forged a new path – implementing EPLAN Cogineer even earlier, already during the bidding phase.

Willems: “The initial idea was that we would take a completely different approach. When we receive a query, we no longer employ our regular cost calculations. Instead, the engineering department just transfers the specifications data from the query into Cogineer. You don’t even need any specialty knowledge of ECAD.” All the customer requirements are simply entered into a configurator interface.

This very simple step enables the automatic creation of a bill of materials, which is transferred to the Omexom costing program via an XML interface. The program then outputs the bid price, which has proven to very closely approximate the actual costs in practice. EPLAN Cogineer is thus already working very reliably in this phase and has cut the time required to prepare a bid by about half.

Additional Time Savings in Electrical Engineering

When the customer accepts the bid and places the order, additional time savings accrue. Willems: “We can then design normal-sized projects in about two to three days – it used to take up to three times longer. And procurement can begin ordering components immediately since the bill of materials is already available.” This speed not only leads to shorter throughput times, it is sometimes also decisive when it comes to orders being placed. Hellmann: “In these cases, it’s not just to our advantage to be able to quickly design and manufacture. Customers also appreciate it when we can show them plans and views of their projects very early on.”

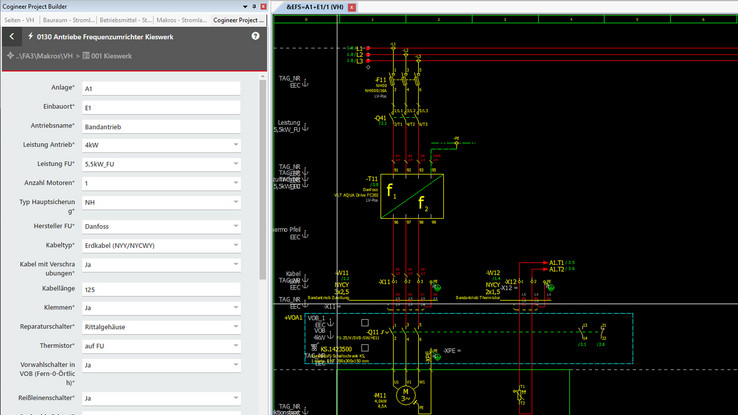

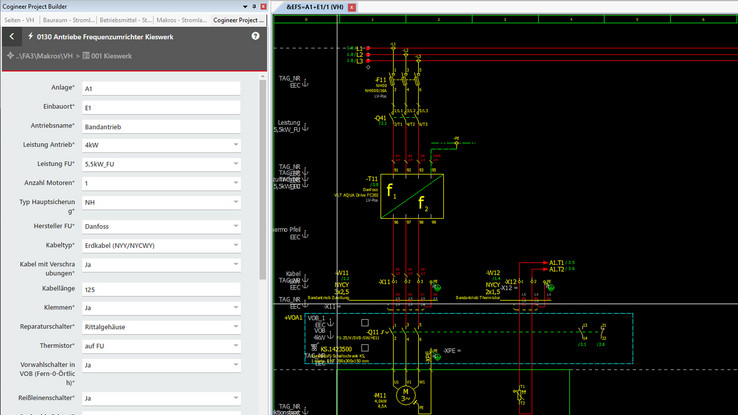

Macros are simply chosen in EPLAN Cogineer to generate schematics.

© Omexom

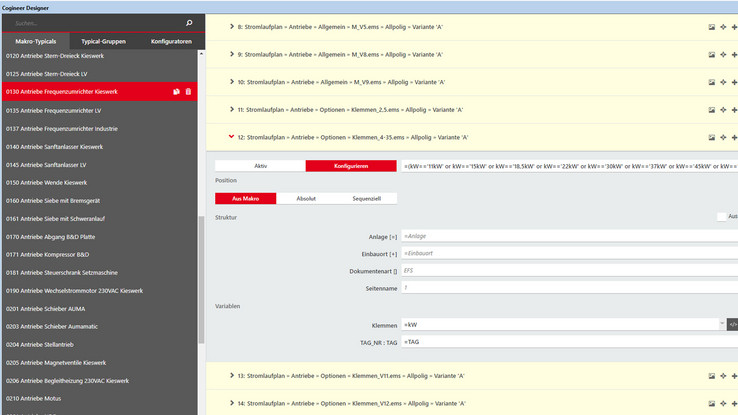

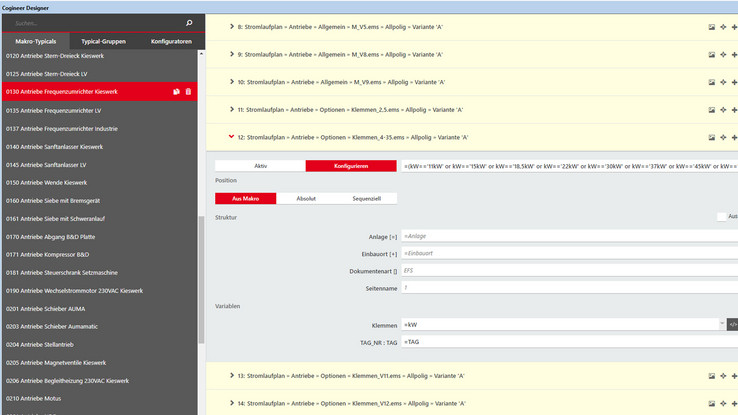

Configuring instead of constructing: this considerably simplifies the work of the electrical engineers.

© Omexom

Macros are simply chosen in EPLAN Cogineer to generate schematics.

© Omexom

Configuring instead of constructing: this considerably simplifies the work of the electrical engineers.

© Omexom

Pro Panel and Rittal – A Good Combination

For panel building, Omexom has been relying for years on EPLAN Pro Panel as the CAD tool and on Rittal as the supplier. Willems: “There are two reasons this makes sense. Rittal components are stored in Pro Panel with a very high level of data quality. This is an added value for us. When we changed from the TS8 to the VX enclosure system, for instance, we simply downloaded the appropriate macros. And, like us, Rittal offers a complete programme from a single source – including accessories for climate control, for instance. This also makes planning and designing easier.”

Simpler Type Approval According to IEC EN 61439

However, the speed of control cabinet engineering isn’t Omexom’s only concern. Accuracy and compliance with standards for designs and design results are just as important. That’s why the company takes very seriously IEC EN 61439, the safety standard for low-voltage switchgear and control gear assemblies. In fact, the company has adapted its processes to this standard’s requirements. Hellmann: “One of the things that helps us is the integrated planning process. We carry out the thermal design of the control cabinet in RiTherm, transfer that data into EPLAN, integrate the Rittal climate control components and document the thermal calculations in compliance with the standards. For us, these are the clear advantages of the integrated value chain, just as we offer it to our customers.”

Thus, as has often been the case, it has paid off for Omexom to be an early tester and adopter of new tools and to forge new paths in the process. Integration into the VINCI Group has brought innovation to an even higher level. Hellmann: “We dialogue extensively with our affiliated companies, including on the topic of ECAD. This brings us further and we can pass along our know-how as well.”

Pro Panel and Rittal – A Good Combination

For panel building, Omexom has been relying for years on EPLAN Pro Panel as the CAD tool and on Rittal as the supplier. Willems: “There are two reasons this makes sense. Rittal components are stored in Pro Panel with a very high level of data quality. This is an added value for us. When we changed from the TS8 to the VX enclosure system, for instance, we simply downloaded the appropriate macros. And, like us, Rittal offers a complete programme from a single source – including accessories for climate control, for instance. This also makes planning and designing easier.”

Simpler Type Approval According to IEC EN 61439

However, the speed of control cabinet engineering isn’t Omexom’s only concern. Accuracy and compliance with standards for designs and design results are just as important. That’s why the company takes very seriously IEC EN 61439, the safety standard for low-voltage switchgear and control gear assemblies. In fact, the company has adapted its processes to this standard’s requirements. Hellmann: “One of the things that helps us is the integrated planning process. We carry out the thermal design of the control cabinet in RiTherm, transfer that data into EPLAN, integrate the Rittal climate control components and document the thermal calculations in compliance with the standards. For us, these are the clear advantages of the integrated value chain, just as we offer it to our customers.”

Thus, as has often been the case, it has paid off for Omexom to be an early tester and adopter of new tools and to forge new paths in the process. Integration into the VINCI Group has brought innovation to an even higher level. Hellmann: “We dialogue extensively with our affiliated companies, including on the topic of ECAD. This brings us further and we can pass along our know-how as well.”