At the SPS: A Real Medium-Voltage Industrial Project

New exhibit and project example for the energy sector

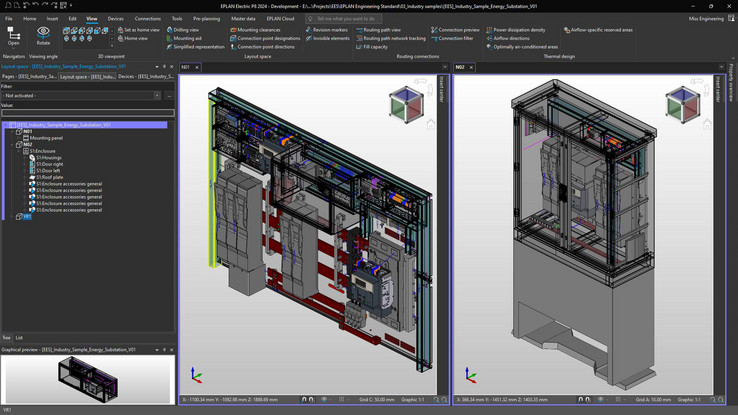

A 3D view of the entire secondary substation in EPLAN Pro Panel, which is being provided as an industrial project at the SPS trade fair.

The power sector has distinct needs and requirements as compared to the automation industry. Different standards and different ways of working can pose challenges for planners and designers. EPLAN and Rittal are therefore presenting a new exhibit of a secondary substation at the most important fall trade fair in Nuremberg. At the same time, a comprehensive industrial project for EPLAN is being provided that takes all aspects of medium-voltage technology into account. The advantage for users is that a special device tag list – an evaluation required for the energy sector – is directly included.

Monheim/Herborn, Germany, 07 November 2023: The electrical engineering designs for automation follow different principles than those for the energy sector, and there’s a need to take action, not just in the field of renewable energies. So that planners and designers are ideally supported in this field, the experts at EPLAN have worked with customers to “pre-design” a standard industrial project – in this case, a secondary substation – that is completely addressed to the energy sector. This EPLAN project will be made available for the SPS trade fair at www.eplan.com and a corresponding exhibit will be presented at the fair in Nuremberg.

At the SPS: an industrial substation project

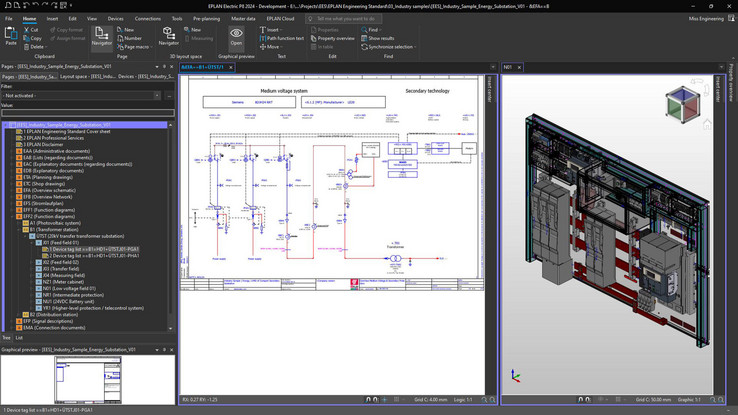

In concrete terms, it involves the engineering of a secondary substation using medium-voltage and low-voltage systems, which will be made available as a project in the EPLAN Cloud. In practice, it can be used to plan and design distribution stations, feed-in stations or mixed systems. Storage systems in the renewable energy sector can also be developed using this as a basis. One of many decisive advantages for users: the device tag list specifically required for the energy industry is already taken into account in the EPLAN software. It also delivers an overview of the devices – for instance which connections are free, which have already been assigned, and exactly where each component is located. Users thus receive a standard-compliant, tried-and-tested example project that includes relevant support for project planning in the field of medium-voltage and low-voltage switchgear systems.

Naturally the traditional EPLAN functions such as single-line and multi-line, 3D designs in the area of assembly layouts, and evaluations, for instance for terminal diagrams, are all supported. Other things are also taken into account in the project, including uninterruptible power supplies (UPS) and the feed-in of power from photovoltaic systems.

The EPLAN Platform 2024 supports electrical engineering project planning in single-pole representation as required for the energy sector – including the digital twin in 3D.

Real practical requirements taken into account

EPLAN Head of Engineering Standard Tom Wolff says: “This is the first time that we’ve put together a project for the energy sector from top to bottom – all while taking into account the industry’s real practical requirements. From planning to operations, to design and manufacturing, all aspects of power engineering are included.” Another interesting point is that the field of manufacturing is also covered because the data can be transferred 1:1 to production.

Simply transfer the data to manufacturing

For example, using the “Copper” module in EPLAN Pro Panel, copper rails, which are frequently used in medium-voltage and low-voltage systems, can be conveniently designed and directly transferred to production. There is also data continuity with the RiPanel Processing Center. The software facilitates efficient production management with various machines from Rittal Automation Systems, for instance the Perforex laser or milling center, the Rittal Wire Terminal WT C for wire assembly, or to copper punching and bending machines from affiliate company Ehrt. The new services offered by EPLAN and Rittal are also of interest here – at the customer’s request, entire low-voltage power distribution systems, including the copper rails, can be pre-assembled by Rittal in Gera, Germany. For engineers using the EPLAN Platform, EPLAN can provide an offer for customised consulting services.

Consistent, end-to-end workflows are the name of the game – and EPLAN and Rittal set the final decisive point: with Rittal ePocket, the system documentation is always up to date. It can be saved, shared and managed in the EPLAN Cloud.